What you need to know about your car Knock Sensor

Don't ruin your car engine. Trial and error sucks

%20(5).jpeg) |

| Know sensor |

%20(4).jpeg) |

| Knock sensor |

.jpeg) |

| Knock sensor |

Circuit Description

A flat type knock sensor (non–resonant type) has the structure that can detect vibration in a wider band of the frequency from about 6 kHz to 15 kHz and has the following features.

- Knock sensors are fitted on the cylinder block to detect engine knocking.

- The knock sensor contains a piezoelectric element which generates voltage when it becomes deformed.

- The generation of the voltage occurs when the cylinder block vibrates due to the knocking. If the engine knocking occurs, in order to suppress it, the ignition timing is retarded.

MONITOR DESCRIPTION

The knock sensor, located on the cylinder block, detects spark knocks. When the spark knocks occur, the sensor picks–up vibrates in a specific frequency range.

When the ECM detects the voltage in this frequency range, it retards the ignition timing to suppress the spark knock.

The ECM also senses background engine noise with the knock sensor and uses this noise to check for faults in the sensor.

If the knock sensor signal level is too low for more than 10 seconds, and if the knock sensor

output voltage is out of the normal range, the ECM interprets this as a fault in the knock sensor and sets a DTC.

If the ECM detects the DTC P0325,P0327 and P0328, it enters fail–safe mode in which the corrective retarded angle value is set to its maximum value.

Symptoms of a Malfunctioning knock sensor

- Reduced engine power

- Hard acceleration

- Check engine light on which will store one or all of P0325, P0327 and P0328

- Transmission will not shift into 4th and 5th gear.

- Excessive fuel consumption

- Engine overheating

Causes of knock sensor malfunctions

- Short circuit

- Damaged sensor

- Sensor not properly bolted down

- Incorrect wiring harness

Inspection Procedure

|

| Knock sensor wiring diagram _Toyota Prius |

Read freeze frame data using the hand−held tester or the OBD II scan tool. Freeze frame data records the engine condition when malfunction is detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air–fuel ratio was lean

or rich, and other data from the time the malfunction occurred.

1. Read the output DTCs

(a) Connect the hand–held tester or the OBD II scan tool to the DLC3.

(b) Turn the power switch ON (IG).

(c) Turn the hand–held tester or the OBD II scan tool ON.

(d) On the hand–held tester, select the item: DIAGNOSIS / ENHANCED OBD II / ENGINE AND ECT / DTC

INFO / CURRENT CODES.

(e) Clear the DTCs.

(f) Put the engine in inspection mode (see page 05–1).

(g) Warm up the engine.

(h) Run the engine at 2,500 rpm for 10 seconds or more.

(i) Read DTC

Results

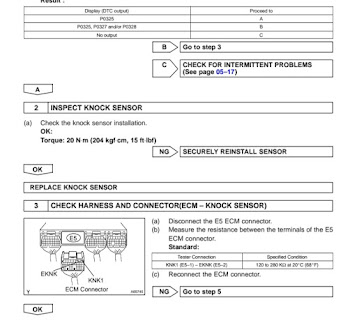

|

| knock sensor inspection method Book an inspection with a car performance diagnostic engineer here. Read what our customers are saying about us here |

%20(1).jpeg)

Comments

Post a Comment

If you have any contribution, pls write it here